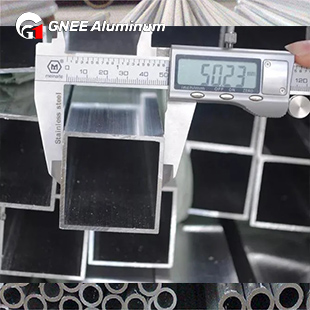

Extruded Aluminum Tubes as a widely used type of aluminum profiles, aluminum tubes are available in square, rectangular and round shapes with different sizes depending on the external dimensions.For customers, the strength of the tube is a very important consideration, which is determined by the aluminum alloy chosen, the wall thickness and the size of the tube.

| Type | Extruded Aluminum Tube |

| Outside Diameter | 6.0mm – 1000mm |

| Thickness | 0.5mm – 60.0mm |

| Length | As customer’s requirements |

| Grade | 1000 Series:1050, 1050A, 1060, 1060A, 1070, 1100, 1200, 1035 3000 Series: 3003, 3105 5000 Series: 5005, 5052, 5454, 5754, 5083, 5086 6000 Series: 6005, 6060, 6061, 6063, 6082 |

| Temper | O, F, H14, H16, H18, H32, H111, etc. |

| Precision | As drawing or as standard |

| Surface Treatment | Chemical Treatments: Anodizing, Electrophoretic Coating, Fluorocarbon Coating, Powder Coating, Wood Grain Transfer Mechanical Treatments: Drawing/Brushed, Polishing, Sand Blasting |

| Size Range OD (mm) | Wall Thickness (mm) |

| 8-150mm | 0.5-20mm |

| Pipe Size Designation | Schedule Number | Outside Dia (inches) | Inside Dia. (inches) | Approx.Wt. (Ibs./lineal ft.) |

| 1/2 | 40 | 0.84 | 0.622 | 0.294 |

| 80 | 0.84 | 0.546 | 0.376 | |

| 3/4 | 40 | 1.05 | 0.824 | 0.391 |

| 80 | 1.05 | 0.742 | 0.51 | |

| 1 | 40 | 1.315 | 1.049 | 0.581 |

| 80 | 1.315 | 0.957 | 0.751 | |

| 1–1/4 | 40 | 1.66 | 1.38 | 0.786 |

| 80 | 1.66 | 1.278 | 1.037 | |

| 1–1/2 | 40 | 1.9 | 1.61 | 0.94 |

| 80 | 1.9 | 1.5 | 1.256 | |

| 2 | 10 | 2.375 | 2.157 | 0.913 |

| 40 | 2.375 | 2.067 | 1.264 | |

| 80 | 2.375 | 1.939 | 1.737 | |

| 2–1/2 | 40 | 2.875 | 2.469 | 2.004 |

| 80 | 2.875 | 2.323 | 2.65 | |

| 3 | 40 | 3.5 | 3.068 | 2.621 |

| 80 | 3.5 | 2.9 | 3.547 | |

| 3–1/2 | 40 | 4 | 3.548 | 3.151 |

| 80 | 4 | 3.364 | 4.326 | |

| 4 | 40 | 4.5 | 4.026 | 3.733 |

| 80 | 4.5 | 3.826 | 5.183 | |

| 5 | 40 | 5.563 | 5.047 | 5.057 |

| 80 | 5.563 | 4.813 | 7.188 | |

| 6 | 40 | 6.625 | 6.065 | 6.564 |

| 80 | 6.625 | 5.761 | 9.884 | |

| 8 | 40 | 8.625 | 7.981 | 9.878 |

| 80 | 8.625 | 7.625 | 15.01 | |

| 10 | 40 | 10.75 | 10.02 | 14.004 |

| Size Range OD (mm) | Wall Thickness (mm) |

| 8-150mm | 0.5-20mm |

| Size O.D.*(inches) | Nominal Wall Thickness | Approx.Wt. (Ibs./lineal ft.) |

| 3/4 | .062 | .201 |

| 3/4 | .125 | .368 |

| 1 | .062 | .271 |

| 1 | .125 | .515 |

| 1-1/4 | .065 | .343 |

| 1-1/4 | .125 | .654 |

| 1-1/2 | .062 | .420 |

| 1-1/2 | .125 | .809 |

| 1-1/2 | .188 | 1.161 |

| 1-3/4 | .125 | .955 |

| 2 | .125 | 1.126 |

| 2 | .188 | 1.598 |

| 2 | .250 | 2.058 |

| 2-1/2 | .125 | 1.383 |

| 2-1/2 | .188.250 | 2.646 |

| 2-3/4 | .188 | 2.266 |

| 3 | 0.125 | 1.691 |

| 3 | 0.188 | 2.487 |

| 3 | .250 | 3.234 |

| 3-1/2 | .125 | 1.984 |

| 4 | .125 | 2.279 |

| 4 | .250 | 4.410 |

| 4 | .375 | 6.395 |

| 4 | .500 | 8.232 |

| 6 | .125 | 3.455 |

| Size Range OD (mm) | ||

| Width | Height | Wall Thickness (mm) |

| 10-220 | 1-120 | 0.5-20mm |

| Size O.D.*(inches) | Nominal Wall Thickness | Approx.Wt. (Ibs./lineal ft.) |

| 1/2 x1 | .125 | .367 |

| 3/4×1-1/2 | .125 | .588 |

| 1×1*1/2 | .125 | .661 |

| 1×2 | .062 | .428 |

| 1×2 | .125 | .809 |

| 1×3 | .125 | 1.102 |

| 1×4 | .125 | 1.430 |

| 1-1/4 x 2-1/2 | .125 | 1.029 |

| 1-1/2 x 2 | .125 | .956 |

| 1-1/2 x 2-1/2 | .125 | 1.103 |

| 1-1/2 x3 | .125 | 1.250 |

| 1-1/2 x3 | .187 | 1.824 |

| 1-1/2 x4 | .125 | 1.544 |

| 1-3/4 x3 | .125 | 1.323 |

| 1-3/4 x4 | .125 | 1.617 |

| 2 x 3 | .125 | 1.397 |

| 2 x 3 | .250 | 2.646 |

| 2 x 4 | .125 | 1.690 |

| 2 x 4 | .250 | 3.201 |

| 2 x 5 | .125 | 1.985 |

| 2 x 5 | .188 | 2.929 |

| 2 x 6 | .125 | 3.279 |

| 2 x 6 | .188 | 3.372 |

| 2 x 6 | .250 | 4.410 |

| 2 x 8 | .125 | 2.837 |

| 3 x 4 | .125 | 1.985 |

| 3 x 5 | .125 | 2.279 |

| 3 x 5 | .250 | 4.410 |

| 3 x 6 | .188 | 3.814 |

| 4 x 6 | .188 | 4.256 |

| 4 x 6 | .250 | 5.586 |

| 4 x 6 | .500 | 10.584 |

| 4 x 8 | .250 | 6.762 |

Advantages of Extruded Aluminum Tube

Lightweight and robust: The low density of extruded aluminum tubes makes them light in weight, but their strength and structural integrity are impressive, making them suitable for both load-bearing and non-load-bearing applications.

Flexible design: The extrusion process allows the flexible shaping of aluminum tubes into a variety of sectional shapes and sizes to meet specific design requirements and applications.

Easy to manufacture: Extruded aluminum tubes are relatively easy to process, cut, weld and assemble, simplifying the manufacturing process and reducing production time and cost.

Aesthetic: Extruded aluminum tubes can be anodized or coated with various surface treatments to enhance their appearance and adapt to different architectural or decorative styles.

Qualification Certificate

Packing and Transportation

About Us

Anyang City, Henan Province, China is the home of Gnee (Tianjin) Multinational Trade Co., Ltd., a professional aluminum company, which deals in domestic and international trade. On-time delivery, excellent value and attentive service are the hallmarks of our business. The company takes serving the society as its business purpose, taking the industry as an example as its business goal, and taking surpassing itself as its enterprise spirit. The group company has been endowed with “down-to-earth people, solid work; Grasp the direction of cultural concept “unity and cooperation” corporate philosophy. Over the years, engineering users from more than 60 countries have established a stable and long-term business relationship with our company. Company leaders welcome customers at home and abroad to negotiate business and exchange technology, and are willing to cooperate extensively with people of insight from all walks of life with high-quality products, excellent service and sincere reputation for win-win and common development.

Cooperative Customer Display

Our Factory

GNEE Extruded Aluminum Tube Benefits:

Design Versatility:GNEE offers a wide range of customization options for extruded aluminum tubes, including a variety of cross-sectional profiles, sizes and finishes to meet specific design requirements.

Environmentally Recyclable:GNEE is committed to sustainability and our extruded aluminum tubes are 100% recyclable, in line with environmental practices.

Expert Support:Our team of experienced professionals provides expert help and guidance to ensure that you find the perfect Extruded Aluminum Tubes to meet your specific project requirements.

Customer Satisfaction:At GNEE, customer satisfaction is our top priority and we strive to exceed expectations with reliable products and excellent customer service.