Aluminum profiles need to go through a process of anodic oxidation when processing. Black aluminum profile is in the anodic oxidation treatment, but also after a process, that is, after the anodic oxidation of the aluminum profile after rinsing, put into the modulation of the dye pool for dyeing can be.

So the production and processing of black aluminum profiles and other colors of aluminum profiles are essentially the same, but there are differences in the dyeing process. At GNEE, we have several sizes of black aluminum profiles, such as 2020 black aluminum profiles, 3030 black aluminum profiles, 4040 black aluminum profiles, 4080 black aluminum profiles and so on.

| BLACK ALUMINIUM EXTRUSION PROFILE |

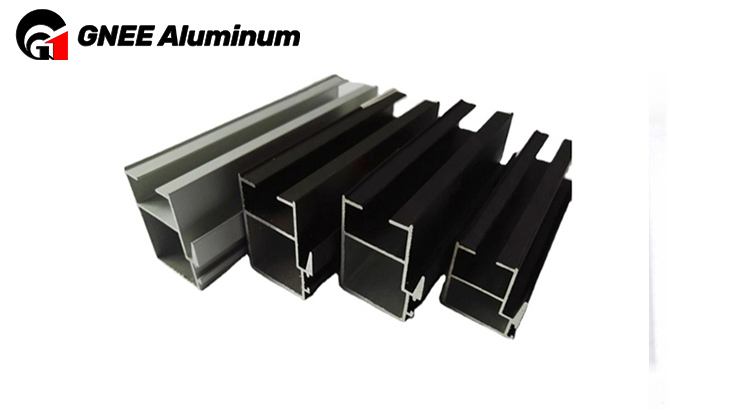

| 1. Description: Aluminum/Aluminium extrusion profile mill finish powder woodengrain anodized for window&door,curtain wall construction, decoration industrial profiles |

| 2. Alloy temper: 6060/6063-T6/T5;6061;6082;6005A;6351;7075;2024;5083 |

| 3. Standard: EN755, ASTMB221, DIN JIS Standard |

| 4. Surface treatment: Mill finishes; anodized; Powder coated, wooden grain, polished, brushed. |

| 5. Application: Construction; window; door; decoration; Architecture and Inustrial etc. |

| 6. Advantage: |

| 1).Factory sell directly, convenient communication,professional technology,Top ranking machines. |

| 2).Almost 40 years aluminum producing experience. |

| 3).Higher R&D skills on Mould cutting, Extrusion processing, Surface treatment, Packing and Loading. |

| 4).Strictly QC systems among the whole production line, we used 99.7% pure aluminum materials for processing. |

| 5).24 Hours online service Patient and Professional, timely response. |

| 6).Export from the biggest Port-Shanghai. |

| 7).No smaller order extra cost |

| 8).TT,LC,DP,OA, Paypal all can accept |

| 9).Free samples |

| 10).OEM service, personalized customization. |

Why choose us

Since 2008, GNEE has been focusing on aluminum profile field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

1. Vacuum Brazing and Controlled Atmosphere Brazing

2. CNC machining

3. Welding

4. Aluminum extrusion

5. Aluminum die casting

6. Sheet metal fabrication covering laser cutting, stamping, drawing and bending

7. Surface coating

GNEE emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

GNEE see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.