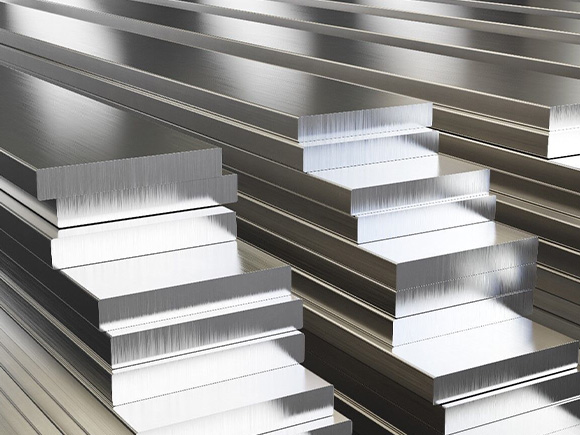

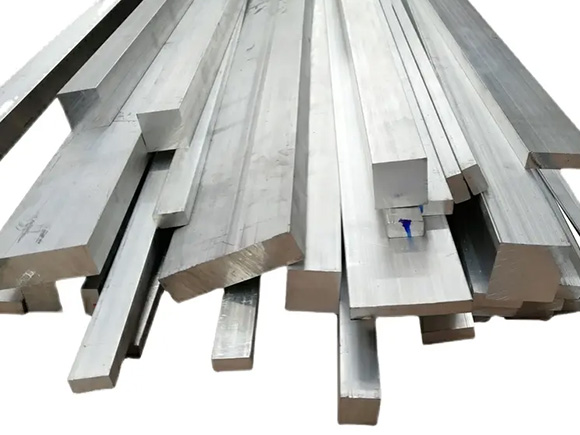

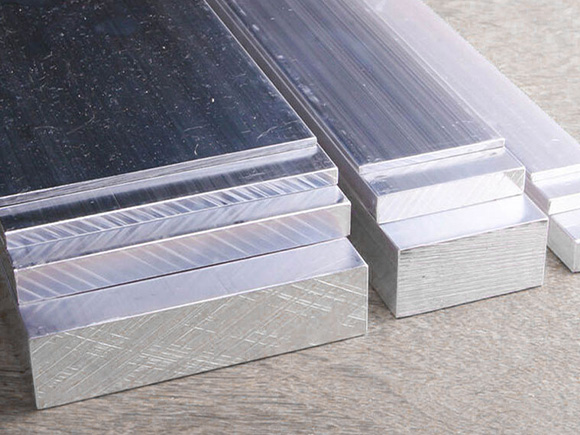

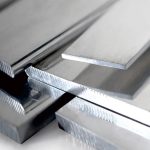

Aluminum Flat Bar is one of the most widely used extrusion materials and can be used in a variety of projects in various industries. Aluminum flat bar is an excellent choice for a variety of constructions because its flat and rectangular faces can be customized to fit the exact size and length you need. Aluminum Flat Bars are also widely used for framing structures, for this application, the bars are simply cut to the appropriate length and then welded or drilled to fit the frame. Especially for construction purposes, a frame made of aluminum flat bar is the right choice because it can hold a lot of weight.

| Material | Aluminum Flat Bar |

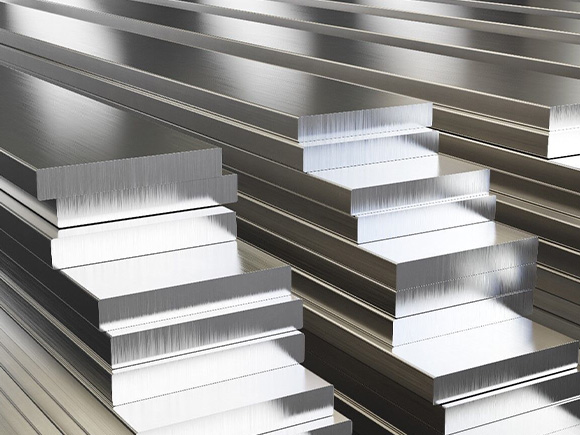

| Width | 10.0mm – 200mm |

| Thickness | 2.0mm – 200mm |

| Anodize Protection Film | 8 – 25 um |

| Powder Coating | 40 – 120 um |

| Grade | a) 1000 Series: 1060,

b) 2000 Series: 2014, 2024, etc. c) 3000 Series: 3003, etc. d) 5000 Series: 5052, 5083, 5086, etc. e) 6000 Series: 6061, 6063, 6082, etc. f) 7000 Series: 7003, 7050 etc. |

| Length | As requirement |

| Surface Treatment | Powder coating, Electrophoresis, Wood grain , Anodized, etc |

| Standard | GB/T 3190-2008, GB/T 3880-2006, ASTM B209,

JIS H4000-2006, etc |

| Deep Process | CNC, drilling, milling, cutting, welding, bending, assembling |

| Techniques | Extruded, Cold Drawn |

| Temper | 0-H112,T3-T8, T351-851 |

Characteristics of Aluminum Flat Bar:

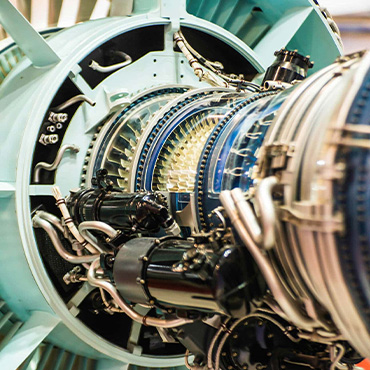

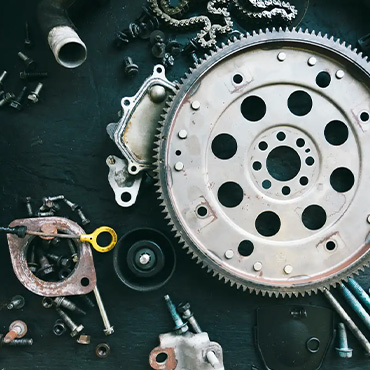

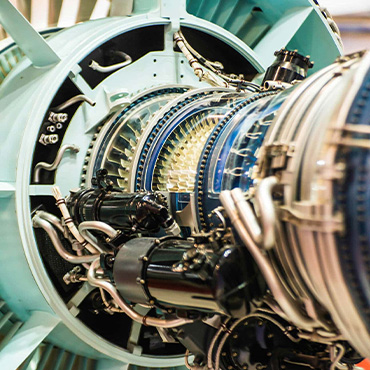

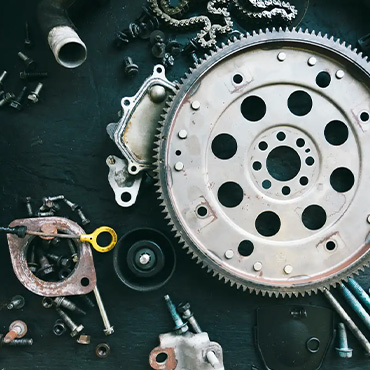

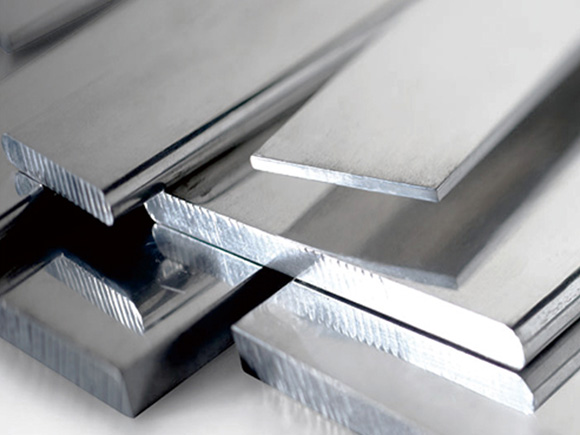

Lightweight: Aluminum Flat Bar is made of aluminum, which has a lower density than other metals, making the product have excellent lightweight properties. This makes it very popular in applications where weight reduction is required, such as in the aerospace and automotive industries.

Corrosion resistance: Aluminum has excellent corrosion resistance, and the formation of an oxide layer can effectively prevent aluminum surface corrosion and oxidation. This characteristic makes Aluminum Flat Bar suitable for outdoor applications and wet environments, able to maintain its appearance and performance for a long time.

Machinability: Aluminum Flat Bar is easy to process and form, and can be customized by cutting, drilling, bending and welding methods to adapt to various design and manufacturing needs.

Structural stability: Aluminum Flat bars provide excellent strength and stability in structural applications and can be used to support important components such as structures and frames.

Quality Assurance

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Large-scale test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

Qualification Certificate

Packing and Transportation

About Us

As a professional aluminum bar manufacturer and supplier, we also offer aluminum strip, aluminum foil, aluminum coil, anodized aluminum sheet, aluminum plate, and more aluminum products. Vietnam, Japan, Korea, Singapore, Indonesia, Philippines, South Africa and more than 50 countries. Please feel free to contact us when you need any of our products.

Cooperative Customer Display

Our Factory

GNEE Aluminum Flat Bar Benefits:

Versatility: GNEE’s aluminum flat bars can be easily machined, formed and welded, allowing for a wide range of applications and design possibilities.

Environmentally Friendly:Aluminum is a recyclable material and GNEE’s commitment to sustainability ensures that aluminum flat bars are environmentally friendly and 100% recyclable.

Customization Options:GNEE offers a wide range of sizes and finishes for aluminum flat bars, allowing customers to choose the most suitable product to meet their specific project requirements.

Expert Support:GNEE offers expert assistance, technical support and personalized service to ensure that customers find the perfect aluminum flat bar solution to meet their needs.