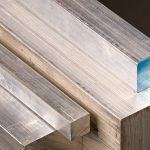

Aluminum rod is a kind of aluminum products, aluminum rod melting and casting methods include melting, purification, impurity removal, degassing, slag removal and casting. GNEE offers aluminum rods in a variety of alloys, including extruded and cold-worked rods in a variety of diameters such as 1060, 2011, 2017, 2024, 3003, 4032, 5052, 5056, 5083, 6061, 6063, 6082, 7003, 7075 and 6101. Sawing with standard and precision tolerances is available.

| Aluminum Bar Shape | Aluminum Bar Grade/Type | Aluminum Bar Sizes |

| Aluminum Flat Bar | Alloys: 2024, 6061, 6063, 6101, 6042, 6082, 7075 Type: Cold Finished, Extruded |

Thicknesses: 0..125”” thru 7” Widths: up to 16″ Stock length: 12’ |

| Aluminum Hexagon Bar | Alloys: 2011, 2024, 6061, 6262, 7075 Type: Cold Finished, Extruded |

Diameter: 0.375″ thru 3.5”. Stock length: 12’ |

| Aluminum Round Bar | Alloys: 2011, 2024, 6061, 6063, 6262, 6042, 6082, 7075 Type: Cold Finished, Extruded |

Diameter: 0.1875″ thru 20” Stock length: 12’ |

| Aluminum Square Bar | Alloys: 2024, 6061, 6063, 6262, 6042, 6082, 7075 Type: Cold Finished, Extruded |

Sizes: 0.375″ thru 8” Stock length:12’ |

| Material | Aluminum Round Bar, Aluminum Rod, Aluminum Alloy Bar |

| Diameter | Ф4.0mm – Ф700mm |

| Grade | a) 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc.

b) 2000 Series: 2014, 2024, etc. c) 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. d) 4000 Series: 4045, 4047, 4343, etc. e) 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc. f) 6000 Series: 6061, 6063, 6082, 6A02, etc. g) 7000 Series: 7003, 7050 etc. |

| Length | As requirement |

| Surface | Mill finish, Silver Finish, Bright Finish |

| Standard | GB/T 3190-2008, GB/T 3880-2006, ASTM B209,

JIS H4000-2006, etc |

| Deep Process | CNC, drilling, milling, cutting, welding, bending, assembling |

| Techniques | Extruded, Forged, Cold Drawn |

| Temper | 0-H112,T3-T8, T351-851 |

Aluminum Bar Production Process:

1. Smelting:

First, the aluminum raw material (usually aluminum ingots or recycled aluminum) is heated to high temperatures, causing it to melt into liquid aluminum. This step is carried out in a furnace, ensuring the complete melting of the aluminum raw material.

2. Purification and impurity removal:

During the smelting process, some impurities and debris may be contained. Therefore, before or after aluminum melting, purification and impurity removal steps are carried out. This can be done by adding chemical purifiers or through other physical and chemical methods. Purification helps to improve the purity and quality of the final product.

3. Degassing:

Aluminum tends to absorb gases such as oxygen and hydrogen during the smelting process, which can adversely affect the performance of the final product. Therefore, in the process of aluminum smelting, degassing is carried out to remove the gas in it.

4. Slag removal:

In the process of aluminum smelting, there may be some oxides and impurities to form a slag. In order to obtain high quality aluminum rods, these dross need to be removed from the molten aluminum, usually by physical and chemical methods.

5. Casting:

When the aluminum has been melted, purified, decontaminated, degassed and slag removal and other early treatment, it can be cast. Liquid aluminum is poured into a pre-prepared casting mold, which is then cooled and solidified to form the desired aluminum rod shape.

Cooperative Customer Display

Qualification Certificate

Packing and Transportation

Since its establishment in 2008, GNEE has been striving to advocate the enterprise spirit of “Sincerity, Faith, Precision and Beauty” with its unique business philosophy, humanized management mode and product diversification. At present, the company covers an area of 2,000 square meters from the beginning to 13,300 square meters, the introduction of imported equipment sets of composite products production line 6, the quality and quantity of the leap to meet the new and old customers at home and abroad on the “GNEE” products of the high standards, strict requirements, but also greatly increased the enterprise’s social and economic benefits.

Our products have been widely used in printing electronics, molds, packaging, aviation, electric power, thermal insulation, aluminum-plastic composite pipes, plates, fiber optic cables, metal products, auto parts and other fields. We have established a certain customer base at home and abroad with our stable quality and sincere service. We will continue to work hard, self-improvement, sincere service, the pursuit of superiority, to occupy the market with quality, to win customers with sincerity. Welcome new and old customers to visit us, negotiate business and exchange experience.

Our Factory

GNEE Aluminum Rod Benefits:

Excellent strength-to-weight ratio: Aluminum rods provide excellent strength while remaining light, making them ideal for load-bearing structures that require weight reduction.

Environmentally friendly: Aluminum is a sustainable material and GNEE is committed to environmentally friendly practices, ensuring that aluminum rods are 100% recyclable and contribute to a green planet.

Wide range of applications: GNEE’s aluminum rods have excellent comprehensive properties and can be used in a variety of industries, including aerospace, Marine, automotive, construction, electronics and general engineering.

Tailored solutions: GNEE offers aluminum rods in a variety of sizes and specifications, enabling customers to choose the most suitable product to meet their specific needs.