| GRADE |

CONDITION |

SHAPE |

TEMPER |

SIZE RANGE |

SPECIFICATION |

| 2024 | COLD FINISHED | ROUNDS | T351 | 1/2″ – 8″ |

AMS 4120 / |

| T4 | 3/16″ – 7/16″ |

||||

| HEXAGONS | T351 |

1/2″ – 2″ |

|||

| T4 | 3/16″ – 7/16″ |

||||

| SQUARES | T351 | 1/2″ – 4″ |

|||

| T4 | 1/4″ – 3/8″ |

||||

| FLATS | T351 | 1/2″X 3/4″ – 4″X 6″ |

|||

| T4 | 1/8″X 1″ – 3/8″X 6″ |

| GRADE |

TENSILE- KSI |

YIELD- KSI |

ELONGATIO- % |

BRINELL HARDNESS |

| 2024 |

68 |

47 |

19 |

120 |

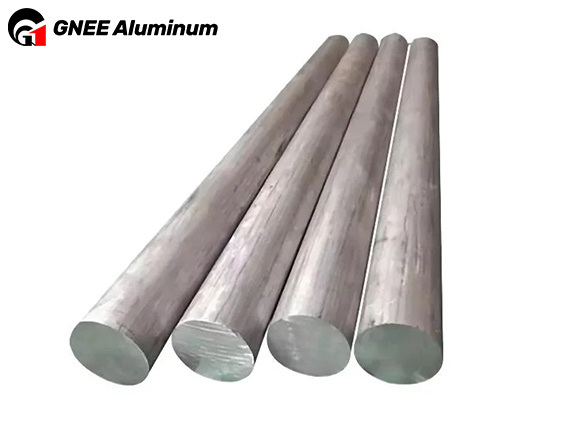

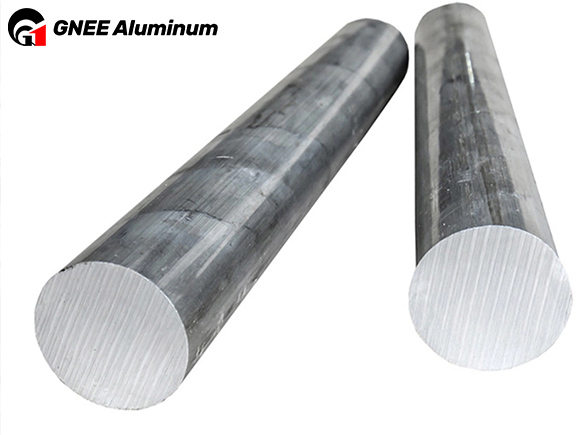

2024 is a high strength aluminum alloy with higher strength than 2011, with adequate work ability. With its high strength and excellent fatigue resistance, it is used to advantage on parts and structures where a good strength-to-weight ratio is desired. 2024 is readily machined at high speeds and gives accurate machining detail with a high finish. 2024 in the annealed condition is easily formed and may be subsequently heat treated. 2024 has good stress corrosion cracking resistance. Since corrosion resistance is relatively low, 2024 is commonly used with an anodized finish or in clad form, with a thin surface layer of high purity aluminum for increased corrosion resistance. Electrical conductivity is 35% of copper

ANALYSIS

2024 Drawn Bar Conforms to ASTM B211, AMS 4120, QQ-A-225/6 2024 Extruded Bar Conforms to ASTM B221, QQ-A-200/3

HEAT TREATING

2024 is an age-hardening aluminum alloy and responds to heat treatment to accomplish the strengthening (aging). The T4 condition is attained by a 920°F heating followed by a cold water quench and aging at room temperature. T6 is attained by the same 920°F and quenched followed by a 375°F for 10 hours and air cooling. Â

ANNEALING

Annealing is done at 750°-800°F for at least 2 hours at temperature, followed by slow cooling in furnace. This will anneal 2024 from a heat treated condition. Annealing 2024 between cold working operations may be done at 650F for 2 hours, followed by air cooling.

The T4 condition is attained by a 920°F heating and cold water quenching. Aging then occurs at room temperature. For T6 condition, use the same 920°F and water quenching procedure than reheat to 375°F for 10 hours and air cool. Other conditions are a result of the T4 condition followed by controlled amounts of cold working. TEMPERING

Is GNEE a trading company or a manufacturer?

GNEE is an integrated trading and manufacturing company to better serve our customers.

Will the products I order from GNEE be delivered on time?

Yes, we are committed to providing the highest quality products and delivering them on time, punctuality and honesty are the core principles of our company.

Do you provide product samples? Are they free?

GNEE provides supply to customers free of charge, but customers need to bear the express freight.

Do your products undergo third-party inspection?

Yes, GNEE is fully third-party inspected to ensure transparency and quality assurance.

How does GNEE ensure product quality?

Each product is produced in a qualified workshop, and GNEE has obtained US FDA certification, EU ROHS compliance, SVHC compliance, and ISO quality management system certification.