Smooth Edges and Superior Corrosion Resistance

GNEE 4545 aluminum profiles feature very smooth edges. Additionally, these profiles offer excellent corrosion resistance. Thanks to their versatile properties, they are an ideal choice for various applications.

Your Preferred 4545 Aluminum Extrusion Profile Manufacturer

GNEE ‘s 4545 aluminum extrusion products are highly recognized by numerous global enterprises. Furthermore, they are favored by most companies for their ease of maintenance and installation.

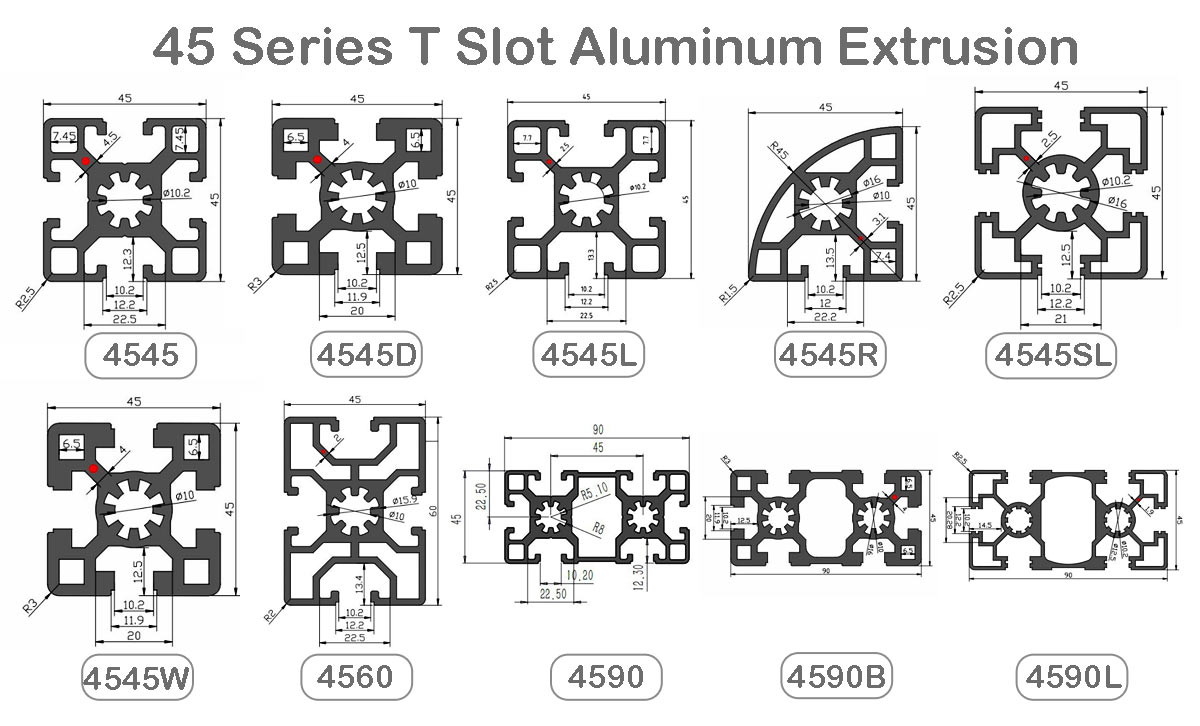

If you need the shape in the picture or other shapes, please contact us , GNEE can customize according to your drawing.

| Item Type | 4545 Aluminum Extrusion |

| Color | Standard: black, silver, and grey, or customized |

| Size | 6mm, 8mm, 10mm |

| Shape | T – Profile, or customized |

| Delivery Time | 15-20 days after sample confirmed & down payment, or negotiated |

| Deep Process | CNC, drilling, milling, cutting, stamping, welding, bending, assembling, Custom Aluminum Fabrication |

| Material | 6000 Series aluminium alloy |

| Profile Options | 15/20/30/40/45/50/60/80/90/100/160 series etc. |

| Free Samples | Yes, we can provide free sample |

| MOQ | Low MOQ |

| Length | Customized length |

| Port | Any Port |

| Temper | T3-T8 |

| Finish | Anodizing, Mill finish, Electroplating, Polishing, Sand blasted, Powder coating, Silver plating, Brushed, Painted, PVDF etc. |

Features

High strength: 4545 aluminum profile has high strength and hardness, suitable for bearing certain mechanical loads.

Corrosion resistance: Aluminum alloy has a natural oxide layer on the surface, which has good corrosion resistance.

Lightweight: 4545 aluminum profiles are lightweight, which helps to reduce the weight of the overall structure.

Easy processing: aluminum alloy is easy to cut, drill, mill and weld, suitable for various processing needs.

Modular design: Standardized dimensions and slot design make it easy to combine and use with other profiles and accessories.

Popular Sizes and Material Quality

The 4545 aluminum profile is well-known for its dimensions ranging from 45mm x 45mm to 90mm. Made from 6000 series aluminum alloy, it offers corresponding toughness from T3 to T8.

Q1: What’s the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and above.

Q2: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

Q3: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q4: How’s the weather resistance for wood grain finish D1010?

A: (1). Powder: Akzo Noble Interpon D1010.

(2). Wood grain film: Italian Menphis.

(3). Standard complied: American AAMA Standard.2603

(4). UV test:1000 hours.

(5). Salt spraying test:1000 hours.

(6). Normal weather: 10 years color guarantee.

Q5: What certification do you have? What’s your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q6: What’s the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.