The 100 series aluminum extrusion is a material widely used in industrial and construction fields, particularly suitable for heavy-duty material handling structures. GNEE is a leading manufacturer and supplier of aluminum extrusion products in China, committed to providing customers with high-quality, professionally designed, and manufactured aluminum extrusions.

GNEE’s 100 series aluminum extrusion boasts the following notable features:

Maximum Strength: This extrusion is meticulously designed and manufactured to ensure extremely high strength under heavy load conditions.

| Product Name | 100 Industrial aluminium profile |

| Material | 6063 aluminium alloy |

| Temper | T5 |

| Surface treatment | Mill finish,powder coating, anodizing, wooden grain coating,polishing,eletrophoresis,PVDF, sanding blasting, etc. |

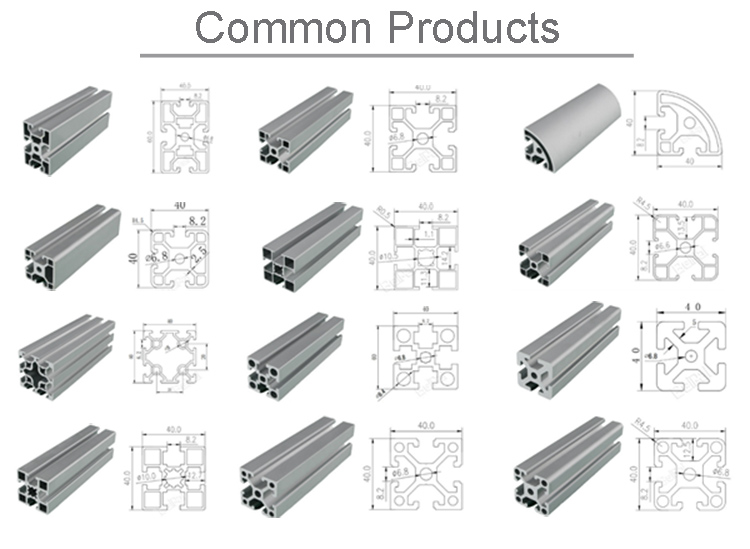

| Size | 20series |

| Slot width | 6MM,8MM |

| Length | 6M |

| Unit weight | 0.5-3.5KG/M |

| Appearance | Normally square,round and T-shaped,or customized |

| Color | Silver,black,blue,wood color,according to clients’ requirements. |

Versatility and Flexibility: The 100 series aluminum extrusion is not only structurally robust but also highly versatile and flexible, suitable for various application scenarios.

Lightweight Design: The 100x100mm aluminum extrusion features 8 slots of 10mm, maintaining structural strength while reducing weight, making it ideal for heavy-duty material handling.

The 100 series aluminum extrusion can be used in a variety of industrial applications due to its robustness and flexibility.

The 100 series aluminum extrusion offered by GNEE is made from 6063 T66 aluminum alloy and undergoes a 15-micron anodizing treatment to ensure material durability and consistency. The standard width and height of the extrusion are both 100mm, suitable for various industrial needs.

To ensure the rapid and secure connection of aluminum extrusions, GNEE recommends the following connectors:

FastLock Connector: This self-tapping barrel connector can form holes in the slot without mechanical processing, facilitating quick assembly.

Central Connector: Requires drilling holes in the extrusion and using workshop tools for installation, suitable for applications requiring high-strength connections.

Angle Bracket: This triangular bracket is suitable for ultra-heavy applications, providing a sturdy and durable connection.

Adjustable Angle Connector: Ideal for applications requiring an inclined working surface, allowing objects to be moved from the ground to working height.

Customized Packaging: We can customize the packaging according to your product specifications, striving to maximize container loading and avoid extra transportation costs, thus achieving greater profit margins for you.

Sample Provision: We can provide samples so you can confirm your order without any worries.

Responsive Support: Any quality or quantity issues will be responded to within 24 hours after receiving your complaints. Problems will be resolved within one week through friendly negotiation.