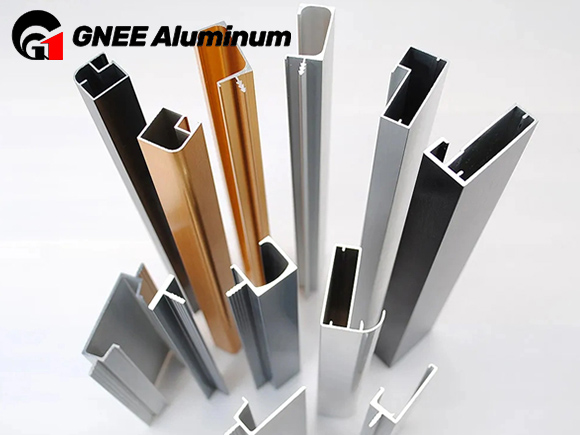

Aluminum profiles for windows refer to aluminum alloy profiles used for manufacturing window frames, window sashes, window grilles, and other window components. Aluminum profiles are extruded into different cross-sectional shapes through an extrusion process. These cross-sectional shapes are designed according to the requirements of the window design, featuring various specifications and functions.

| Alloy | 6060,6063,6061,6082,7075 |

| Anodize thickness | normally anodize thickness is 9-11um. |

| Powder coating thickness : | normally powder coating thickness is 60-80um. |

| Standard : | GB/T5237-2008 Chinese Standard |

| Trade terms: | Ex-factory , FOB GUANGZHOU/SHENZHEN,CIF ,CNF |

| Finish products | System aluminum window&door, Extrem narrow sliding door series |

1. Specifications and Dimensions of Aluminum Profiles

The main size series for aluminum door and window profiles include 40, 45, 50, 55, 60, 65, 70, 80, 90, and 100mm. The size series used for aluminum alloy windows are relatively smaller, while those for aluminum alloy doors are larger. The marked size series for aluminum doors and windows do not necessarily mean that the cross-sectional shapes and dimensions of the profiles are the same. The cross-sectional shapes and dimensions of aluminum alloy door and window profiles in the same size series can be quite complex and must be analyzed and considered based on specific drawings.

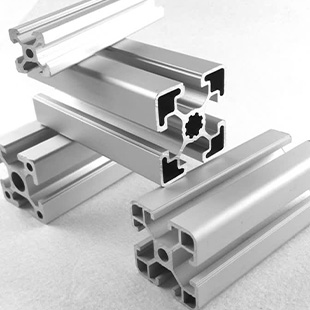

Aluminum door and window profiles can be classified into solid profiles and hollow profiles based on their cross-sectional shapes, with hollow profiles being more commonly used. The wall thickness of aluminum door and window profiles should be no less than 1.4mm for windows and no less than 2mm for doors. The length dimensions of aluminum door and window profiles can be classified into fixed length, multiple length, and variable length. The fixed length generally does not exceed 6 meters, while the variable length is not less than 1 meter.

2. Chemical Composition and Mechanical Properties of Aluminum Profiles

Aluminum doors and windows use aluminum-magnesium-silicon series aluminum alloy profiles. The chemical composition, besides aluminum, includes silicon, iron, copper, magnesium, manganese, chromium, titanium, and zinc. The magnesium content is between 0.45-0.90%, and the silicon content is between 0.2-0.6%. The mechanical properties of aluminum door and window profiles are as follows: the tensile strength (σb) is not less than 157N/mm²; the specified non-proportional elongation stress (σp0.2) is not less than 108N/mm²; the elongation rate is not less than 8%; the hardness (HV) is not less than 58.

3. Production Process and Equipment of Aluminum Profiles

The production of aluminum door and window profiles involves four processes: ingot preparation, extrusion forming, heat treatment, and surface treatment.